The practical solutions from KTS Kunststofftechnik for fastening pipe clamps to thermally insulated house facades ensure a clean wall seal and prevent cold bridges.

In order to achieve simple, fast and especially safe installation of waterfall pipes on house walls, we have developed two methods. The

KTS – PIPER Long-shaft dowel

and the

KTS – IS-RSD Insulating dowel

avoid not only a messy and weather-sensitive weak point on the wall of the house, but also the emergence of cold bridges.

Previous, problematic and unclean fasteners

Due to energy saving measures and as a contribution to the reduction of CO² emissions, more and more existing residential buildings and project buildings are being equipped with thermal insulation facades. The installation of downpipes on thermally insulated facades is problematic in many respects. Firstly, the application by means of the impact mandrel is not only difficult and messy, but also represents a cold bridge directly into the masonry. In addition, when hammering through the plaster, it threatens to break out in places. The makeshift patching of the holes causes a loose hold in the wall and provides additional exposure to the elements. In addition, the fastening of the impact mandrel is critical, as the facade insulation makes it very difficult to install in the masonry. We have two solutions to these problems.

KTS fastening solutions for pipe clamps

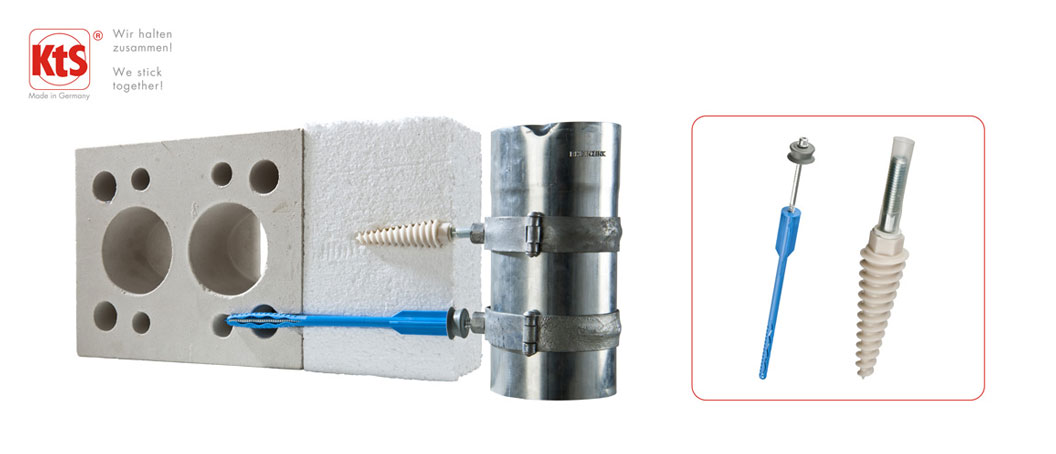

According to the current state of the art, the fastening should either be firmly anchored in the thermal insulation or in the load-bearing substrate. We offer two specially developed mounting solutions for this purpose. The KTS – IS-RSD an chor with a special hanger bolt (10 x 100 mm), a cover cap as well as a grommet for thread protection of the screw and the KTS – PIPER long-shaft anchor with a self-tapping screw pin and a cover cap.

Fastening into the insulation material with KTS – IS dowels

The pre-mounted hanger bolt is screwed into the insulation material (e.g. polystyrene or rigid foam boards) using the KTS – IS-RSD anchor. The Torx drive at the head end of the screw facilitates assembly. Due to the threaded protection placed on top, subsequent plastering of the insulation material is possible without any problems. The grommet prevents contamination of the screw thread. After plastering, the cover cap protects the drill hole from the effects of weather and provides a clean wall finish. The exposed, metric M10 male thread allows for easy installation of common push-in clamps used to attach downspouts.

This method offers significant advantages. Drilling into the solid substrate is not necessary. The assembly takes place, simply and quickly, directly into the insulation material. The fact that the hanger bolt is fully seated in the plastic anchor and also in the thermal insulation means that no cold bridges can occur. The KTS – IS-RSD dowel always ensures a firm hold.

Fastening directly into the masonry with KTS – PIPER long-shaft anchor

If the downpipe has to be connected directly to the masonry, it is recommended to use the KTS – PIPER long-shaft anchor with screw pin. This solution, developed together with a master plumber, consists of the KTS – PIPER long-shaft anchor, a self-tapping screw pin and a cover cap. The recommended anchoring depth of 90 mm, guarantees firm hold and safety. The cover cap supplied, with its shaped drip nose, diverts the run-off rainwater even before it reaches the facade, thus preventing moisture from penetrating the thermal insulation and the masonry. The self-tapping screw pin additionally enables installation without long-shaft anchors, for example in aluminum and steel structures. This method ensures thermal separation as well as uniform load distribution, from the anchor tip to the outer edge. The available dimensions of 10 x 180 mm, 10 x 240 mm and 10 x 280 mm enable through-fitting through almost all insulation materials established on the market.

You can find more information about KTS sanitary products

here

.